The key performance characteristic of the AT24 VFD series is ultra-adaptability: the technical specifications support superior versatility. This is a widely applicable, cost-effective solution for motor control. Intelligent design results in features that achieve an unchallenged level of performance in the field, due to:

- Specialized performance

- Four core lines (UC, UH, SD, and MP), and four specialty lines (LE, SR, RT, and DW)

- Multiple software packages available

- Multiple accessories and external device compatibility

- Multiple power blocks

- Several service programs available for configuration and commissioning

- Uniform requirements for service, diagnostics, and repair, for simplified use

1. The product lines within the series.

The AT24 VFD Series includes eight separate lines, each with distinctive features and recommendations for use or application suitability.

1.1. Lines designed for general industrial applications:

AT24 VFD Line UC

- Plastic or metal enclosure, wall mounting

- IP20/IP21 enclosure, operating temperatures from -25°С to +40°С (up to +55°С with power derating)

- Designed for installation in electrical rooms or automatization panels

- Single design for operating with voltages from 380 V to 480 V

- Power range from 0.37 kW to 400 kW

AT24 VFD Line UH

- Metal enclosure, wall mounting

- IP55 enclosure, operating temperatures from -25°С to +40°С (up to +55°С with power derating)

- Designed for installation at industrial sites with a high dust and/or moisture environment. Unit features a specially adapted cooling channel

- Single design for operating with voltages from 380 V to 480 V

- Power range from 5.5 kW to 400 kW

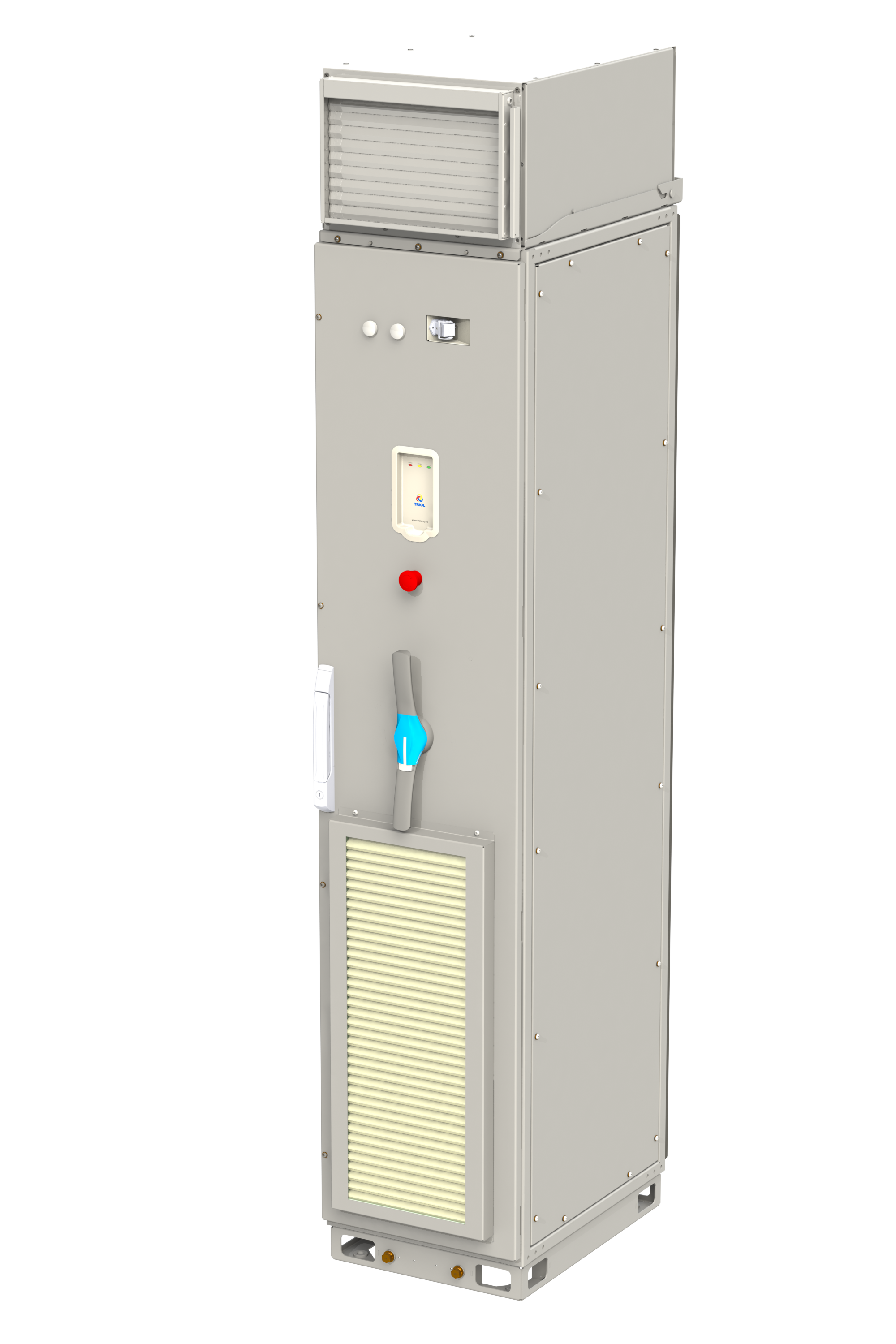

AT24 VFD Line SD

- Metal cabinet, floor installation

- IP21/IP54 enclosure, operating temperatures from -40°С to +50°С

- Designed for installation in electrical rooms and industrial sites

- Rated voltages: 380 V, 480 V, 690 V

- Power range from 110 kW to 1600 kW

AT24 VFD Line MP

- Designed for use with multi-motor systems and high high-power motors

- Metal cabinet suitable for floor installation, with modular rectifier and VFD cells

- IP21/IP54 enclosure, operating temperatures from -40°С to +50°С

- Designed for installation in electrical rooms and industrial sites

- Rated voltages: 380 V, 480 V, 690 V

- Power range from 300 kW to 6000 kW

1.2. Product lines designed for specialized applications:

AT24 VFD Line LE

- Designed for use as part of a elevator control panel

- Suitable for use with induction and synchronous winches, with various types of encoders - absolute (enDat, sin/cos, SSI), incremental

- Plastic or metal suitable, wall mounting

- IP20 enclosure, operating temperatures from -25°С to +40°С(up to +55°С with power derating)

- Designed for installation in electrical rooms or elevator control panels

- Single design for operating with voltages from 380 V to 480 V

- Power range from 4 kW to 30 kW

AT24 VFD Line SR

- Designed for use with sucker rod pumps (SRP)

- Features specialized algorithms to optimize well flow rate when installing a downhole controller

- Metal enclosure, wall mounting

- IP55 enclosure, operating temperatures from -40°С to +50°C

- Designed for outdoor installation

- Rated voltages: 380 V, 480 V

- Power range from 5.5 kW to 75 kW

AT24 VFD Line RT

- Designed for use with progressive cavity pumps (PCP) and sucker rod pumps (SRP)

- Features specialized algorithms for motor operation in case of loss of input voltage

- Metal cabinet suitable for floor-standing installation

- IP54/NEMA3R enclosure, operating temperatures from -25°С to +50°С

- Designed for outdoor installation

- Rated voltages: 380 V, 480 V

- Power range from 15 kW to 200 kW

AT24 VFD Line DW

Complete solution designed for use in drilling rigs. Includes the following types of electrical equipment:

- Complete transistor unit for top drive control

- Complete transistor unit for mud pumps control

- Complete transistor unit for tower-winch unit control

- Complete transistor unit for drilling rig equipment control: mud pumps, tower-winch unit, rotor

- Low-voltage device for additional equipment for drilling rig control

- Modular, all-welded, heat-insulated container in an IP54 enclosure suitable for operating temperatures from -45°С to +45°С

- Designed for outdoor installation

Triol AT24 VFDs offer a versatile range of solutions for:

- General industrial applications (pumps, fans, compressors, mills, conveyors, crushers, mixers, rolling mills, expellers, extruders, escalators, cranes, centrifuges, expanders, paper and textile machines, etc.)

- Elevators and elevator control stations;

- Shipbuilding (thrusters, power supply for steam generators, anchor winches)

- Drilling rigs (top drive systems, mud pumps, tower-winch, rotor tables)

- Oil industry equipment (sucker rod pumps, progressive cavity pumps)

The adaptability of the AT24 series also lies in the ability to select the VFD for various operating conditions:

I. Load type:

- Normal duty (ND) use the VFD with mechanisms with low overload (fans, pumps). The drive overload in normal mode is 120% for 60 seconds.

- Heavy duty (HD) use of VFDs with mechanisms with significant overload (mills, conveyors, lifting mechanisms). The drive overload in heavy mode is 150% for 60 seconds.

II. Installation location suitability:

- Electrical room or electrical panel

- Industrial sites with high levels of dust and/or moisture

- Outdoor;

- Inside mines

- Onboard a ship

- In sea air and maritime conditions

III. Operating temperature suitability:

- in cold conditions (from -45°C)

- in hot conditions (up to +55°C)

IV. Altitude suitability:

- Standard altitude conditions up to 1000m above sea level

- High altitude conditions up to 4000m above sea level (with output power derating)

2. High-quality motor control.

High-quality control is achieved by vector control based on an accurate mathematical model and algorithms for automatic determination of the motor parameters.

Sensorless vector control (open-loop) provides:

- Speed control accuracy better than 10% of the rated motor slip

- Torque control accuracy better than 10% of the rated value

Sensor vector control (closed-loop) provides:

- Speed control accuracy better than 0.1% of the rated speed

- Torque control accuracy better than 5% of the rated value

This makes it possible to perform precise control, ensure trouble-free operation of the system, and maximally protect the motor and the mechanism from breakdowns.

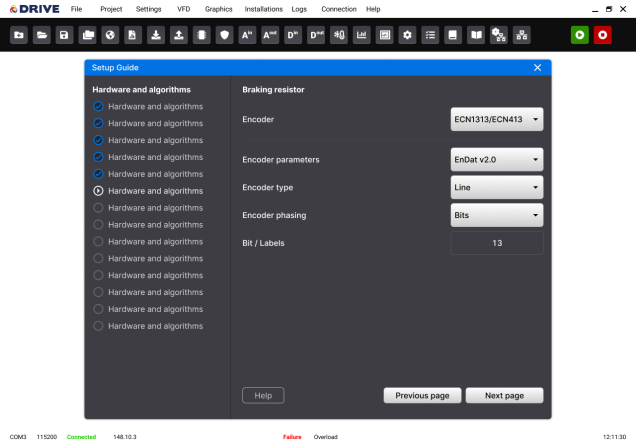

Vector control is often perceived as very difficult to understand and customize. Many people abandon the use of vector control in favor of an understandable scalar control (V/f ratio) in order to avoid complexities in setup and quick start-up. The Triol AT24 VFD Series simplifies vector control and makes it more accessible by using a step-by-step process:

- Go to the Quick Setup menu.

- Enter the rated parameters of the motor from its nameplate.

- Start automatic identification of the motor parameters with or without rotation.

- Allow the Quick Setup Wizard to perform multiple motor starts, to optimize control quality (VC speed controller auto-tuning is performed).

- If there is a speed sensor on the motor (encoder), run an automatic check of its rotation direction.

That's it, your AT24 VFD is ready!

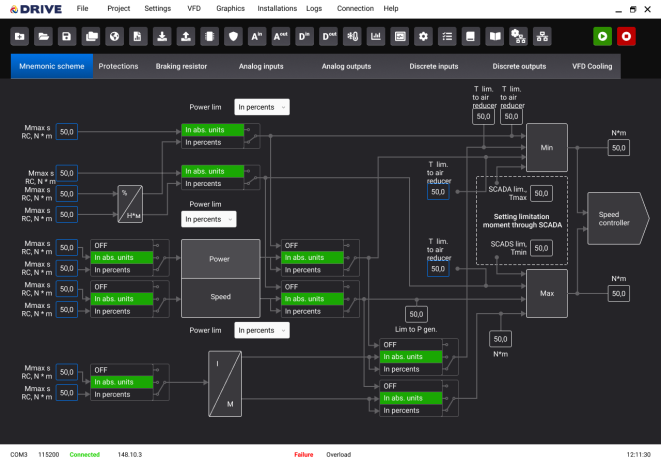

3. Selection of Cutting-Edge Software Packages

All Triol AT24 VFDs are supplied with a basic software package, which includes the necessary functions for simple and convenient use. The basic software package includes such necessary functions as a PID controller, rotating motor flying start, automatic restart, skip frequencies, keeping zero frequency, ModbusRTU protocol via RS-485 interface, logging alarms and warnings.

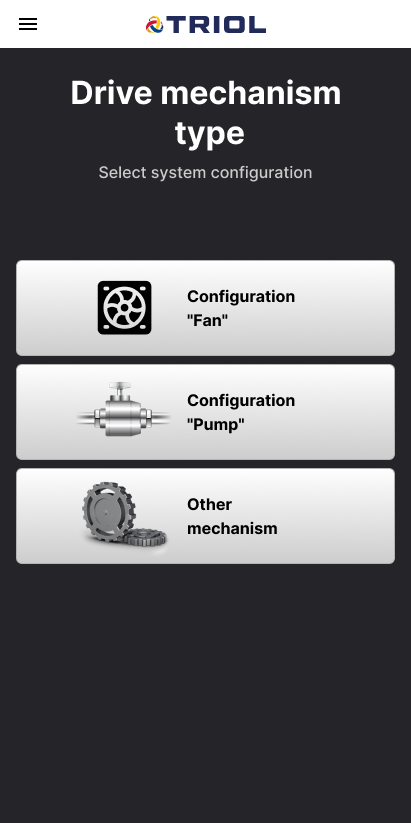

Specialized expansions are available, depending on performance needed and use cases. Advanced algorithms expand the functionality of the AT24 VFD for various applications, including specific equipment cases: "Elevator/Escalator", "Multi-Motor", "Master-Slave", "Oil Production", "Automation", "Pump", "Fan", "HVAC", "Conveyor", "Mill", "Tower Crane", "Beam Crane", "Winding Machine", "Decanter”, “Centrifuge", "Marine Winch" and others.

Software packages can be installed or changed via Wi-Fi or by using the TriolDrive PC software. Regardless of the unit configuration, commissioning can be managed quickly and on-site: all that's required is to install the necessary expansion units, update the software package, and the AT24 VFD is ready for your project.

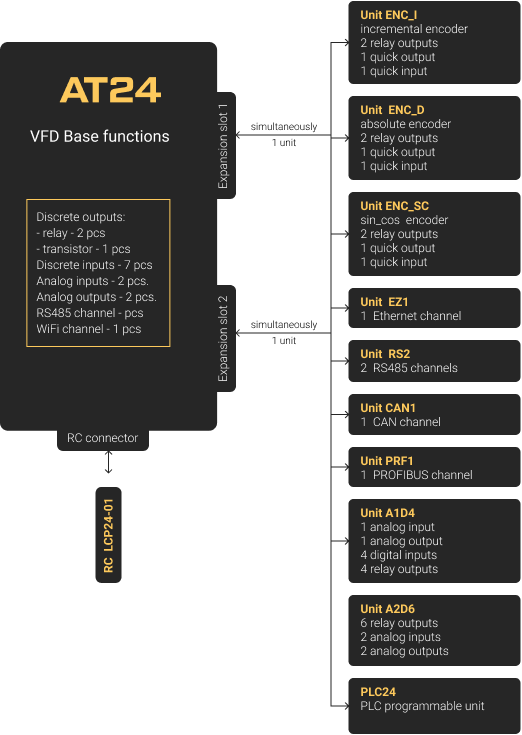

4. Auxiliary Unit Options for Connecting External Devices.

TTriol AT24 VFD Series units feature built-in capability for integration into larger automated systems:

- 6 programmable digital inputs

- Pulse input (up to 50 kHz)

- Safe torque off input (STO)

- 2 relay outputs

- Pulse output (up to 50 kHz)

- 2 analog inputs with software operating mode selection, 0-10 V / 4-20 mA

- 2 analog outputs with software operating mode selection, 0-10 V / 4-20 mA

- 2-wire RS-485 interface with ModbusRTU protocol

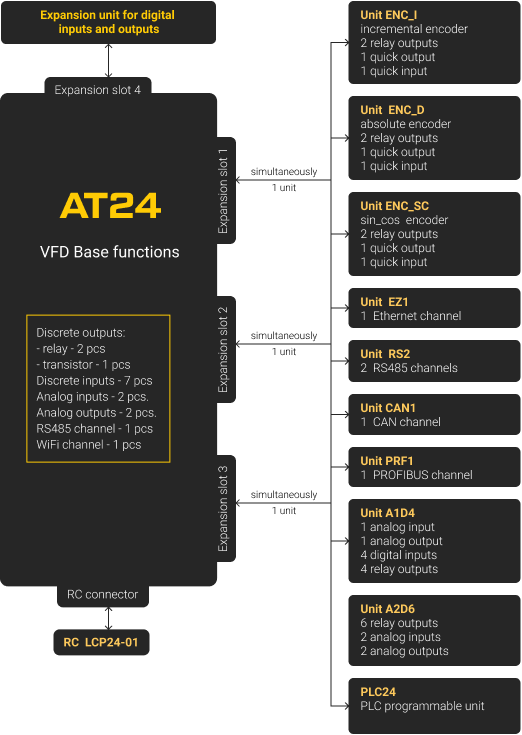

If your project requires more robust performance, the Triol AT24 VFD Series can be expanded to include up to four units operating simultaneously:

I/O expansion units:

- A1D4 Unit: 1 analog input, 1 analog output, 4 digital inputs, 4 relay outputs

- A2D6 Unit: 2 analog inputs, 2 analog outputs, 6 relay outputs

Interface units:

- EZ1 Unit: ModbusTCP protocol

- CAN1 Unit: CANopen protocol

- PRF1 Unit: Profibus protocol

- RS2 Unit: ModbusRTU protocol (2 channels)

Expansion units are available for connecting speed feedback sensors (encoders), for precise operational control:

- ENC_I Unit: Expansion unit for connecting incremental encoders (TLL/HTL), 1 pulse input, 1 pulse output

- ENC_D Unit: Expansion unit for connecting absolute encoders, 1 pulse input, 1 pulse output

- ENC_SC Unit: Expansion unit for connecting sine-cosine encoders, 1 pulse input, 1 pulse output

Our PLC24 unit allows you to configure functions for the programmable logic controller for AT24 VFD Series units. This increases unit adaptability for a wide range of automated processes, without requiring additional devices.

Implementing this automation solution makes it possible to deploy an external PLC, with additional modules and a cabinet/panel for installation. The user-friendly TriolDrive PC software allows You to configure basic PLC functions, without advanced programming skills.

The Triol AT24 VFD Series is simple to integrate into your existing systems and reduces costs required for project automation.

Variants are available for connecting expansion units to Triol AT24 VFD UC Line for 0.37-5.5 kW power.

For Triol AT24 VFD UC Line for 0.37-5.5 kW power: any two expansion units are available for simultaneous installation.

Connection options for expansion units for Triol AT24 VFD UC Line for power from 7.5 kW, and for UH Line for power from 5.5 kW.

For Triol AT24 VFD UC Line for power from 7.5 kW (5.5 kW for UH Line), there are three universal expansion slots and one additional slot for a digital I/O expansion unit.

5. Power Unit Options Available.

One of the important challenges in using VFDs is ensuring quality power supply performance. The AT24 VFD's wide range of input and output filters solves this potential problem with ultimate efficient performance.

Accessory units for specialized performance include:

- Braking chopper: AT24-BC in a separate IP54 enclosure

- Regenerative unit: AT24-RU is suitable for operation both with a single VFD and within a group with a common DC bus

Input filters are used to reduce the negative impact of the VFDs for the mains:

- EMC filter AT24-EMC, for category C2 according to EN61800-3

- Line choke AT24-LC, to suppress higher voltage harmonics and protect the VFD from voltage surges in the main

- Passive filter AT24-PF, which minimizes distortion from VFD to mains, according to the requirements of the IEEE 519 standard

Output filters are used to increase the service life of VFD motors:

- AT24-DU/DT filter reduces rate of voltage rise on the motor (dV/dt) to 500 V/μs, which allows use of a longer motor cable line

- Sine-wave filter AT24-SF provides sinusoidal output current and line voltage, which reduces influence on the insulation and minimizes currents on the motor bearings

- Common mode filter AT24-CM reduces high frequency common mode currents and extends motor bearing service life

Depending on the model, filter installation may be performed either inside the VFD enclosure or by an external unit.

6. Selecting, Commissioning and Setting Service Programs

The service program TriolSelect, executed under Windows, allows you to quickly and accurately select the exact nomenclature among hundreds of series nomenclatures.

Configuration, commissioning and control methods for Triol AT24 VFD Series models are also varied. If a keypad is your preferred entry method, a graphic keyboard with LCD display is available. This remote control can be placed on the AT24 VFD case, or used remotely.

Controlling the AT24 VFD with the TriolDrive PC utility program provides easy configuration, both with drive connection and offline. User-friendly interface and diagrams simplify the setup process.

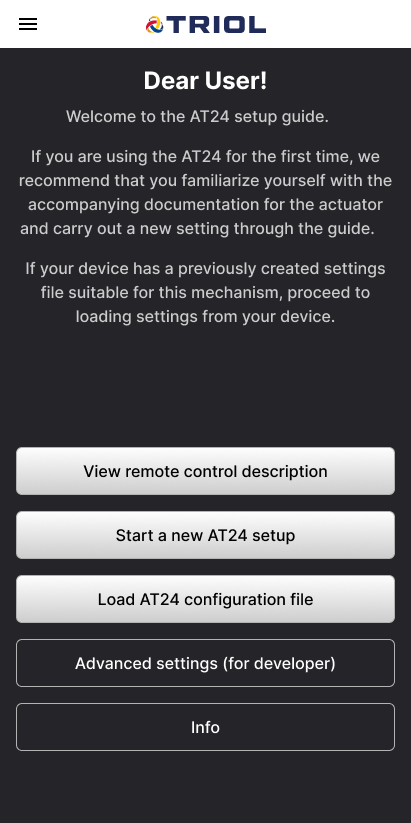

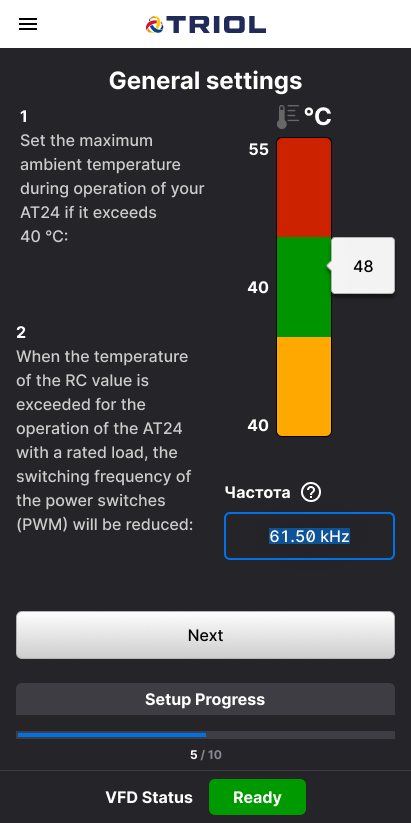

Wi-Fi remote control connection and setup are also available, using a smart phone, tablet, laptop, or other device via the built-in web interface, with step-by-step configuration instructions. This option provides access to full array of VFD parameters and the ability to generate graphs of processes or selected values.

Transferring configuration settings from one drive to another is also available via Wi-Fi remote control. No additional devices or wires are required, which saves time and effort.

You can also connect via Wi-Fi to Triol Wizard – a step-by-step and error-free Triol AT24 setup wizard. It will guide you through all the stages of setting up the AT24 until it is put into operation. Well-thought-out steps and instructions will allow you to put the product quickly and reliably into operation.

7. Uniform requirements for service, diagnostics, and repair, for simplified use.

We've engineered convenience into the Triol AT24 VFD Series. Expansion units, terminals, interface, interactive tips, and service software are uniform across all models in the series, ensuring units are “comfortable” in every sense of the word.

Triol manages the complete product production cycle in-house, and components are sourced from world-leading suppliers. We have contracted with our partners to ensure spare parts are available for at least ten years, even in the case of products removed from serial production.

The minimal requirement for spare parts for servicing a VFD fleet significantly reduces your purchase and storage costs. Unified design and software solutions across the entire AT24 VFD Series do not require additional time for worker retraining or documentation review.

So, we have briefly introduced you to the main advantages of the Triol AT24 series products. In our opinion, these advantages make Triol AT24 the best option for solving most of the tasks where a VFD is required.

When operating a mechanism with a VFD, various benefits can be achieved:

- energy saving

- high control accuracy

- comfort of movement

- optimization of raw material consumption

- improvement of product quality or development of new varieties

- increasing the resource of the motor, mechanism, valves, and pipes

- reducing the influence on the supply mains and the absence of voltage drops during starts

- increase in productivity

- minimization of manual labor

- ease of maintenance and revision of mechanisms and others.

This variety of applications and the variety of possible solutions require significant knowledge, experience and skills from designers, application specialists and architects of automation systems. Triol’s special training and education programs for specialists are available online and we will be happy to answer your questions in our webinars or on social networks.

We are pleased to note that we see new opportunities to make Triol AT24 one of the leaders in its field. Over the next year, we plan to post extensions to this article. Additional paper will be devoted to one of the listed advantages.

Besides, during this time we have planned several unique implementations in different countries, on different continents, which will be relevant to our professional readers. We look forward to telling you about them; it will be interesting!

Apply IUUU low-voltage Triol AT24 - make your technologies perfect!

Don’t miss your elegant solutions!

- Product news

- Events

- Discounts

- Product portfolio innovations

More news

|

|

|

|

|

Google

Google